Welcome to Milstead Farm Group

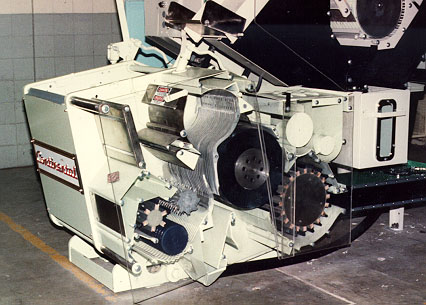

| Milstead Farm Group is Central Alabama’s most modern cotton gin. We take great pride in creating value for our customers. The implementation of technologies and practices allow us to maximize the value out of each module harvested. |

Our Mission

To provide area producers with a modern and efficient cotton gin plant to maximize value to the cotton and cottonseed produced by the area cotton producers.